A Walk on the Valve Side

I was at an off-channel reservoir construction site and took a little stroll... down into a 10-foot tall butterfly valve buried deep underground. NBD.

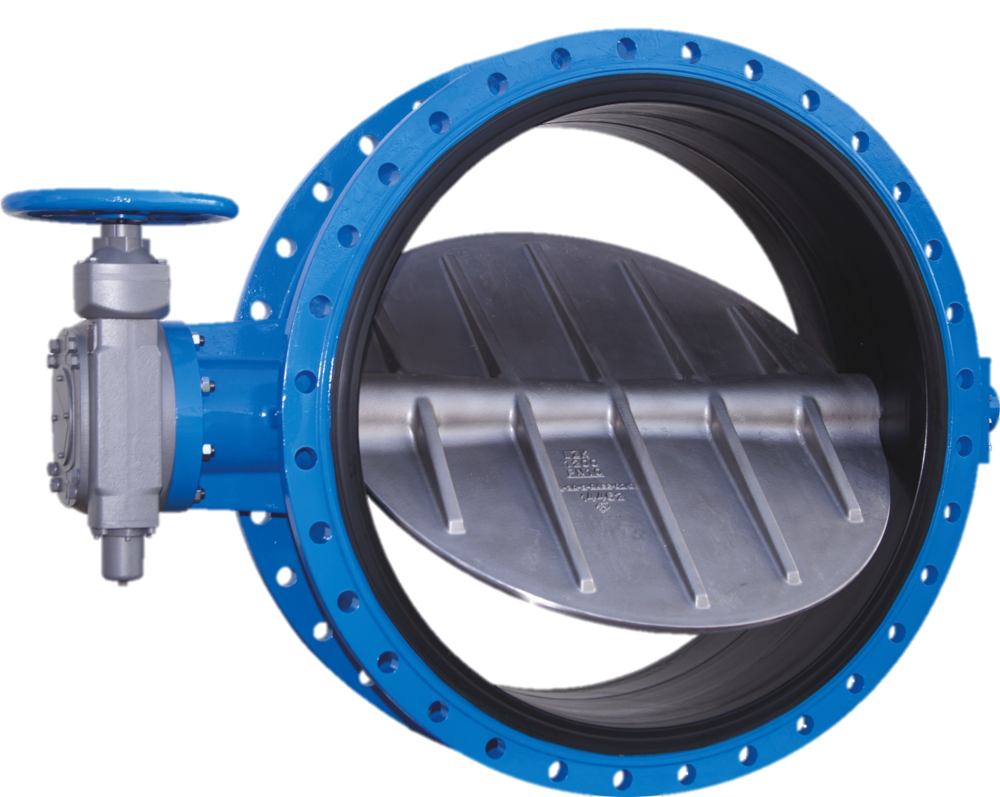

This is what a butterfly valve looks like. It has a little swinging disc that closes to shut off flow through a pipe. Generally we use a BFV for larger pipes because they require less energy to open/close, are lighter weight so they need less structural support, and close faster than other valve types. They can get clogged up with junk if there is debris in the pipe (which is why plug valves are used for wastewater). There is also a large friction loss (reduction of hydraulic energy) because there is a physical object (the disc) in the middle of the pipe that the water has to whoosh past.

I left the construction trailer (office) to take a look at the current construction. This BFV is the main shut-off valve for draining the reservoir. Think of it as a bathtub with a drain. This valve is the drain stopper. So it's one of the most important valves on site and needs to have all sorts of inspection during construction.

I entered the pipe sliding down the inside of it holding onto a rope, secured at ground surface. I was only able to do this because I'd previously had confined-space training.

I trekked a little bit down to the valve and here we are! Inside a valve!

When we went through it, the pipe was wet because the contractors had been cleaning out silt brought in by Hurricane Harvey a year earlier. They put in this platform to walk along inside the pipe but there were parts of the walk that didn't have the platform. Our inspector seemed concerned that I might be ruffled if my biz casual clothes got wet. It was sweet but he wouldn't have been concerned about the guys on the site. Even the ones dressed for the office like me.

I'd walk through a valve in black-tie if I got the opportunity! Well, with my PPE and steel toed boots, of course.

Goliath Valve Installation

THIS is a very large pump station.

The valves are the red slices you see connected to the yellow piping.

It takes about 2 days and 3 field crew to hand tighten one valve. We require them to tighten to 1260 ft-lbs in 480 ft-lb increments. In a star pattern of course. ⭐

[video width="1920" height="1080" mp4="http://andromedadumont.com/wp-content/uploads/2018/07/VID_20180418_112950.mp4"]

Beastly Pipe

This piping is all over the pump station area on site. There are multiple levels of it so the contractor dug out a HUGE hole, fitted the first layer, backfilled, fitted the second layer... really it's just like cake decorating. Here they are doing the welding collars on some of the pipe.

It's like the humans ate an Eat Me cake! I love it.

Reading: Dark Places by Gillian Flynn. I need this.

Working: I'm writing a production well report for a well to supply a mid-sized town here in Texas. We did the design for the well (depth, size, location, screen specs), the construction oversight, and analysis following the pumping tests on the aquifer. Now is the boring part that makes it a job. But also I really like the boring part because it closes everything together in a lovely little bow.

Listening: Mom Jean Jams. Try saying that three times really fast.